Facilities Management is a very active area of technology deployment and continuous innovation.

Non-Intrusive Inspection technologies, advanced analytic software using machine learning, and remote/robotic access are being adopted on a constantly growing number of offshore assets. These technologies can ensure access to hard-to-reach areas, increasing safety and reducing the requirement for manned entries in pressure vessels and inspection of storage tanks.

Emission reduction is another important priority for technology efforts in this area, with improved operational monitoring and controls, leading to power management efficiencies and reductions of flared or vented gas.

There is a significant improvement of digital systems for Facilities Management, with the growing adoption of electronic devices and wireless communication offshore, their effective integration with operations and maintenance systems, asset surveys and full ‘digital twin’ applications.

Main areas of Operators’ technology focus spreads across design, installation and operational phases of the subsea systems

Advances in pipeline design, and more capable subsea processing equipment enable more distant and cost-effective subsea tie-backs for the development of UKCS resources

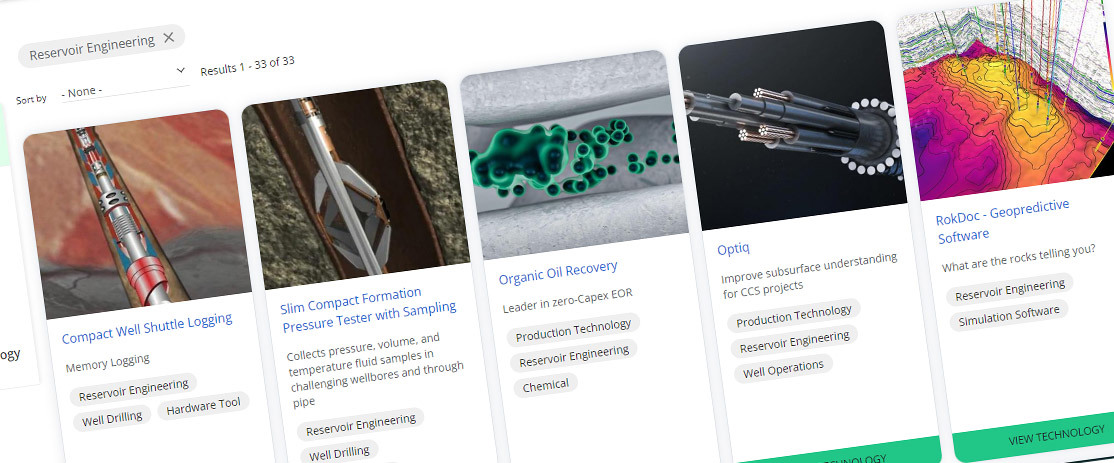

There is widespread interest in these technologies, with 12 Operators carrying at least 5 Reservoir and Well Maintenance technologies in their Plans, and 11 more Operators reporting at least 1 technology

Many technical solutions for Facilities Management are proven technologies, with circa one third in the early deployment stage or pilot stage

Whilst the majority of technologies are provided and deployed by vendors and suppliers, in circa 40% of cases Operators take an active role in the development or customisation of the solutions for their assets’ needs

Readiness definitions: Early Development (TRL 1-4), Late Development/Pilot (TRL 5-7), Early commercialisation (TRL 8), Proven (TRL 9)

Facilities management technologies in Equipment Monitoring & Reliability are focussed on remote condition monitoring technologies, including analysis software using AI and ML to reduce the need for offshore manned inspections with both cost and safety benefits. New this year are integrated 3D model-based asset management systems, software for production optimisation and emission reduction, control room assistant software to monitor for developing operational issues and advanced analytics trip prediction using ML.

- Streaming Data - Rotating Equipment - Development of PI AF/PI Vision environment to use streaming data for condition monitoring of critical asset rotating equipment

- TRL9 Proven Technologies

- Motion Amplification Camera - Motion Amplification to visualize vibrations in standard HD video. Early detection of vibrating equipment. Visualization of actual vibration behaviour. Fast & simple screening of vibration issues

- TRL9 Proven Technologies

- Fully integrated 3D model based Asset Management system - Develop a fully integrated 3D model based Asset Management system/platform that enables efficient and effective visualisation of equipment characteristics, using a digital twin philosophy. Type of data sources will include MAXIMO APM/PM/MCDR data; live PI data; as-built documentation and RBI and cumulative risk status.

- TRL9 Proven Technologies

- Optimise Offshore Plant Performance - Offline predictive analytics Machine Learning and AI to Monitor plant performance in association with OPEX and optimise running parameters to reduce GHG emissions

- TRL9 Proven Technologies

|

Technology Example: Asset surveillance & monitoring Pre-configured digital modules – rapid deployment System wide model to identify best practice deviations/anomalies Prioritised threats & actions |

|

- KAIROS - Control Room Assistant – Kairos Control Room Assistant(CRA) is a software solution that combines sensor outputs, Harbour’s SoPs and the Process Engineers and Operator’s expertise so-as to pre-alert against developing operational issues

- TRL 9 Proven Technologies

- YETI - Emissions Optimisation – Software to manage production parameters for Emissions optimisation

- TRL 8 Early Commercialisation

- Advanced analytics trip prediction – Operator has built a machine learning model that has analysed the historical performance of the CO2 train and we are in the process of hooking this to real time data so that we can predict process trips at least 15 minutes before they occur. Historic real time data was used to develop and build a machine learning model. The aim of the model was to give at least 15 minutes pre-warning of a trip occurring and for 50% accuracy

- TRL 5-7 Late Development/Pilot

Integrity Monitoring & Inspections continues to show increasing numbers of new NII technologies and robotic access systems that are being adopted on greater numbers of assets. Operators focus is on technologies using AI & ML to identify anomalies from live inspection data. New this year are wide area UT monitoring, black light cameras and IoT based CUI automated monitoring systems.

- Phased Array Ultrasonic Testing for Pipework - Use of Phased Array Ultrasonic Testing with FlexoFORM or new this year - NovoSound probes for topsides pipework inspections

- TRL9 Proven Technologies

- Drone Inspection - "Caged drone used for internal visual inspection of slugcatcher and fingers at St Fergus. The drone video is then used to generate a digital twin. Drone for fabric maintenance coating inspections of NUI’s “

- TRL9 Proven Technologies

- ToolTec caisson inspection - Deployed to undertake external inspection of the SW caissons to determine wall thickness and assess their condition/integrity. The unit built for caissons >40” diameter. This technology enabled us to avoid deploying people on ropes down towards the splash-zone (high-risk, highly weather-sensitive, and some areas that cannot reach)

- TRL9 Proven Technologies

|

Technology Example: ToolTec have developed a range of cleaning and inspection tools that can be deployed from a platform, capable of cleaning and obtaining inspection data from varying sizes of caissons and conductors. |

|

- Wide Area UT Monitoring - Permanent monitoring of UT (Ultrasonic Testing) area rather than a single point

- TRL9 Proven technologies

- Black Light Camera - Inspection for water leaks from seawater tank in Cormorant Alpha legs below gas tight floor which avoids use of personnel

- TRL 9 Proven Technologies

|

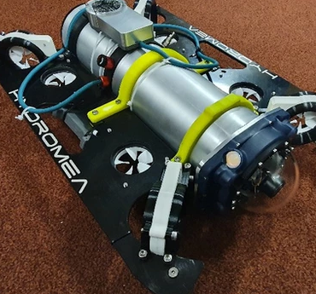

Technology Example: Hydromea’s focus is to develop a purpose-built system that would be able to take HD scans of the interior of a ballast water tank and take wall thickness measurements. a tether-less semi-autonomous underwater drone uses situational awareness algorithms to navigate a tank and photo-telemetry software to provide 3D heat maps of spots requiring maintenance. |

|

- Anomaly Defect Recognition - Analysis of historic and live inspection data to automate detection anomaly defects to improve the accuracy and efficiency of for integrity management and work execution. GDi

- TRL 5-7 Late Development/Pilot

- Use of long-range UT or alternative method for inspecting corrosion under Pipe Supports - Use of long range UT or alternative method for inspecting corrosion under pipe supports

- TRL 5-7 Late Development/Pilot

Facility Integrity Repairs sub-category has seen a resurgence in numbers of technologies. Operators report 3D printing for rapid part manufacture, maintenance access systems, and tablets & scanning tools for rapid identification of structural fabrication activities. Emerging technologies include laser rust removal and vibration modelling. New for 2023 is the additive manufacturing of metal and polymer valve parts.

- 3D Manufacturing - Using advanced manufacturing techniques such as 3D printing to replace parts such as pump impellers and heat exchangers

- TRL9 Proven Technologies

- Bespoke Clamp & Tool to allow conductor repair - NSP Conductor Repair Project NS16 Conductor

- TRL9 Proven Technologies

- Caisson and conductor integrated cleaning and protective coatings -Rope access assist platform and large-scale application tooling for external cleaning and Stopaq application. Caisson and conductor integrated cleaning and Stopaq application is needed to extend life of these elements.

- TRL9 Proven Technologies

- Use of Tablets and scanning tools Offshore for fabrication - portable hand-held scanner

- TRL9 Proven Technologies

- Laser Surface Preparation - Laser Rust removal to time efficiently remove rust for inspection and recoating

- TRL 5-7 Late Development/Pilot

- Kibosh Rapid Pipe Leak Sealing Clamps - Kibosh leak sealing repair clamps. Technology established in domestic/commercial plumbing sector.

- TRL 5-7 Late Development/Pilot

|

Technology Example: The Kibosh Rapid Emergency Pipe Repair Clamp stops leaks immediately, once a Kibosh pipe repair clamp is fitted, the metal or plastic pipe can continue to function normally again under pressure |

|

- Flow induced vibration modelling - Initial investigation of potential vibration levels on Knarr FPSO with Rosebank production

- Equinor (Rosebank) TRL 1-4 Early Development

- Additive Manufacturing of Metal and Polymer valve parts - Increased difficulties in availability of raw materials causing impact on cost and schedule of the valve parts. The utilisation of the additive manufacturing (AM) also improves reuse of resources reducing the requirement for new raw materials. The AM technology is based on 3D printing of parts and is still in development with a number of API standards being issued/developed for the process requirements, associated QA/QC requirement being developed.

- TRL 1-4 Early development

Maintenance & Operations sub-category continues to show increasing number of new technologies that are being adopted on a greater number of assets. Operators’ focus is on technologies that utilise digital and data to enhance the connectivity of the offshore worker in the platform environment, virtual assets, digital twins, connectivity between onshore and offshore control rooms and heads up displays. New this year are joint integrity management databases and control room assistant technology. Emerging technology includes a high-performance data centre module.

- Visual Asset Management - PDMS / Laser PointCloud model / R2S - PDMS / Laser PointCloud model / R2S systems are used to visualise the assets onshore in virtual reality with a view to minimise surveys offshore..

- TRL 9 Proven Technologies

- Onshore Support Control Room - A copy of the Mariner offshore control room onshore

- TRL 9 Proven Technologies

- Platform Digital Twin - Digital twin platform to enable digital work flow and quick, accurate and seamless access to information for each asset.

- TRL 9 Proven Technologies

- Onshore/Offshore Control Room linkage - Set up onshore Operations Rooms where key onshore asset support staff can provide direct and timely support to offshore operations

- TRL 9 Proven Technologies

- SIMPro Joint Integrity management database - Transition from the paper-based flange integrity management process to the cloud-based database for improved and simplified record keeping, auditing and improved integrity of the mechanical joints. Database also contains all relevant documentation. Challenges are to fully adopt SBT make-break cycle and provide a mobility solution to allow tablet-based use of the database at site.

- TRL 9 Proven Technology

- Kairos emission radar which is a bolt on to Kairos CRA - Achieving transparency of where emission as coming from on a data to bases to the offshore teams to help them make decisions on energy and flaring optimization & reduced emissions.

- TRL 8 Early Commercialisation

- Connected Worker - Digital Heat Maps & Operational Risk Identification for Maintenance & Operations Optimisation.

- TRL 8 Early Commercialisation

- Hololens smart 'heads up display' glasses - Pilot trial Hololens accelerator program to help visualise plant modifications and projects.-

- TRL 8 Early Commercialisation

|

Technology Example: HoloLens to construct and display 3D models, achieving a highly integrated display of virtual information and on-site scenarios for trainings conducted in mixed reality. The use of HoloLens will provide users virtual access to historical data of entire production environments, visual displays of gas reservoirs, wellbores, buried pipeline models, to ensure technicians can fully grasp the specific conditions of the allocated sites. |

|

- Asset55 iQ Control - Deployment of Asset55 iQ Control will improve the management of outage and maintenance campaigns through systematic planning and preparation of activities in a single location. It will also improve re-work for future campaign activities by historising workpacks for larger standard scopes.

- TRL 9 Proven Technologies

- Caisson & Conductor stabilising system - Polyurethane poured system to stabilise conductors within their guides

- TRL 5-7 Late Development/Pilot

- High performance data centre module - High performance data centre modules that will utilize excess power from topsides and / or wind turbine

- TRL 1-4 Early Development