Operators’ technology plans are reflecting industry priorities to reduce offshore greenhouse gas emissions.

Reduction of flaring and venting emissions are targeted, for instance, through technologies able to recover flash gas and/or improve flare efficiency.

Operators are targeting power emissions through more efficient equipment, alternative low-carbon fuels, hybrid power systems, and/or replacing conventional power generation with renewable power from offshore windfarms or the shore.

Interest in carbon storage is growing rapidly and innovative technologies are needed in areas ranging from site characterisation, well and facility design, and the Monitoring, Measurement and Verification of CO2 injection over the lifetime of the carbon store.

Net Zero technologies

In line with industry commitments to the North Sea Transition Deal to reduce their greenhouse gas emissions going forward, interest in technologies to address Flaring & Venting, Energy Efficiency, and Low-Carbon Power has grown significantly

Companies with the largest operational footprint in the UKCS show greatest interest, but in general there is a broad presence of these technologies in the reported plans (18 Operators out of 55)

Net Zero is defined in this document as a ‘cross-cutting’ category, where technologies are an integral part of the offshore asset lifecycle (chart below)

Net Zero technologies by area of application

Technology solutions for Net Zero tend to be less proven than in other more mature categories, with about two thirds being at first deployment or still under development.

Operators are getting more involved directly in the technology development cycle in this area, often in partnership with vendors and the NZTC.

Readiness definitions: Early Development (TRL 1-4), Late Development/Pilot (TRL 5-7), Early commercialisation (TRL 8), Proven (TRL 9)

Flaring & venting monitoring and reduction technologies are an increased focus as Operators align with achieving zero routine flaring, open reporting aligned with the principles of OGMP 2.0 and anticipating methane’s inclusion in UK ETS proving strong combined drivers. New this year are liquid ring compressors for flare gas recovery, and emission radar for flaring optimisation to reduce emissions.

- Flare Gas Recovery facilities/ Vapour Recovery systems– recovering & reprocessing gas to sales export

- TRL 9 Proven Technologies

- Amine Vent Capture & Sequestration - Capturing the CO2 from the Amine Vent on the Elgin PUQ and injecting into nearby reservoir zone

- TRL 9 Proven Technologies

- Optimise Plant Performance - Install X-PAS Emissions software on NCP and NSP. Monitor plant performance in association with OPEX and optimise running parameters to reduce GHG emissions

- TRL 9 Proven Technologies

| Technology Example: | |

|---|---|

|

X-PAS™ is a digital solution for complex assets to predict threats, prevent system trips and reduce maintenance costs. |

|

- Liquid Ring Compressor - Flare Gas Recovery, Liquid ring compressors can compress nearly all gases and vapors without any metallic parts contacting one another

- TRL 9 Proven Technologies

- Kairos Emission Radar - Achieving transparency of where emission as coming from on a day to day basis to the offshore teams to help them make decisions on energy and flaring optimization & reduced emissions.

- TRL 8 Early Comercialisation

- Methane RPA Survey - unburnt hydrocarbons/methane site-level survey using remote piloted aircraft flown from onshore to offshore installations, improving safety, reducing risk, reduces OPEX

- TRL 8 Early Commercialisation

| Technology Example: | |

|---|---|

|

Liquid ring compressor uses a liquid ring formed from the operating liquid, instead of a mechanical piston, as an energy carrier to compress gases and vapours. Liquid ring compressors can compress nearly all gases and vapours without any metallic parts contacting one another. |

|

- Autonomous Methane Measurement - Measurement of methane emissions from unburnt fuel gas, unburnt flare gas, venting and fugitives. Use of ATEX rated autonomous measurement device to detect and quantify baseline methane emissions and abnormal events using TDLAS measurement technique.

- TRL 5-7 Late Development/Pilot

- Flare Combustion Efficiency – asset/site-level assessment of flare system combustion efficiency to determine reportable methane slip

- TRL 5-7 Late Development/ Pilot

Net zero technologies targeting low carbon power/electrification are focussed on substituting/reducing the dependency on fuelling gas turbine on-platform power. This includes platform electrification from grid or from local floating offshore wind, hybrid power systems, topsides and subsea power packs for short-term energy storage, and alternative low carbon fuels for turbines/ engines. New this year are wave energy for subsea power systems and further renewable power sources from floating wind and power from shore.

- Power From Shore / Renewables - Review various options to connect the currently operating asset to renewable and /or onshore connection to reduce emission and increase PE

- TRL 9 Proven Technologies

- TRL 9 Proven Technologies

- Floating Wind generator - Reduce GHG Emission from Power Generation topsides. Connection to floating wind or floating wind and wave to decarbonise the electrical power generation on operated facilities.

- TRL 9 Proven Technologies

- TRL 9 Proven Technologies

- Hybrid power system - Hybrid power system providing a maintenance free solution in the form of solar panels, providing power to the platform whilst charging batteries. Two small lean-burn diesel-engine driven generators will provide energy in case the renewable system fails.

- TRL 9 Proven Technologies

- TRL 9 Proven Technologies

- Renewable Subsea Power - Wave Energy - Reviewing opportunity to supply power to subsea systems for new wells and remedials on existing wells

- TRL 8 Early Commercialisation

- Battery storage - On-site battery system to generate value for the site as well as providing additional power resilience. Benefits: Reduced electricity bill, reduced maintenance cost, fuel gas saving, additional back-up power supply, GHG emission reduction.

- TRL 5-7 Late Development/Pilot

| Technology Example: | |

|---|---|

|

Containerised Battery storage systems, reduce spinning reserve and provide a back-up source of power. |

|

- Alternative Fuel - Alternative low carbon fuel provision for site services. Pilot scale technology deployment of green hydrogen equipment at Easington Terminal being planned.

- TRL 5- 7 Late Development/ Pilot

- TRL 5- 7 Late Development/ Pilot

- Mocean/Verlume – Wave energy converter subsea power system – generation of local power and storing in subsea battery packs, removing need for long umbilicals and additional power/ comms from platforms

- TRL 5-7 Late Development/ Pilot

- TRL 5-7 Late Development/ Pilot

- Low Carbon Power Solutions - Review wind power solutions & grid connection for the CNS as part of a collaborative effort with energy suppliers and other operators

- TRL 1-4 Early Development

Energy Efficiency technologies are gaining focus amongst Operators as a cost-effective way of reducing emissions by reducing fuel consumption and boosting exported production over the remaining asset life. New this year are using data analytics to optimise operations and reduce emissions, passive purge burners to reduce high burner overhaul costs and removing the need to maintain a spinning reserve. Emerging technology includes a high-performance data centre module using excess power from topsides and/or wind turbines.

- Peak load management - Emissions Reduction – Utilising load bank and battery technology to manage peak load and reduce need for higher diesel generation requirements

- TRL 9 Proven Technologies

- Compression Rewheels - Use of latest technology to rewheel compression low lower plant pressures and increase plant efficiency with correctly sized compression

- TRL 9 Proven Technologies

- TRL 9 Proven Technologies

- Optimizing GT Efficiency - Looking at various technologies to increase the efficiency of the simple cycle GTs offshore driving compression and power gen.

- TRL 9 Proven Technologies

- TRL 9 Proven Technologies

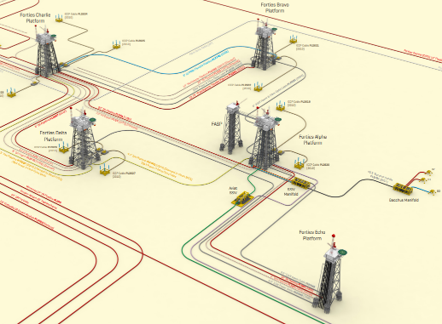

- Power sharing across assets - Installation of power sharing across assets through installation of subsea power umbilical. Reducing the requirement to run as much power generation reducing GHG emissions and operating costs

- TRL 9 Proven Technologies

| Technology Example: | |

|---|---|

|

Apache Forties ring main – linking of platforms via subsea cables to share power generation and reduce number of gas turbines in the field |

|

- Emissions Reduction - Data analytics solution to optimise operations and reduce emissions

- TRL 9 Proven Technologies

- TRL 9 Proven Technologies

- Passive Purge Burners (SGT200) - Coking on the current SGT200 dual fuel burners on Judy SGT200 causes significant reliability issues during fuel transfer between Diesel fuel to Gas. This leads to both lost production in some cases, inefficiency running of power generation with an additional spinning reserve and but also a very high burner overhaul cost for the facility with multiple burner changes per year after running on liquid fuel.

- TRL 9 Proven Technologies

- TRL 9 Proven Technologies

- Electrifying Mech GT Drivers - Once power from shore / renewable is available the GTs could be converted to high speed electrical motors. Review available feasibly to change the GTs to e-motors to reduce CO2 emissions and increase PE and lower OPE.

- TRL 8 Early Commercialisation

- Gas Compression analytics - Use of data science methods to improve gas compression up time

- TRL 5-7 Late Development/Pilot

- TRL 5-7 Late Development/Pilot

- Unmanned surface vessel for offshore pipeline survey - Unmanned surface vessel for offshore pipeline survey to increase survey frequency on old aged pipelines on a cost-effective basis and monitor any freespan development even closer to be in a position to better develop long term remedial plan

- TRL 5-7 Late Development/Pilot

- TRL 5-7 Late Development/Pilot

- High performance data center module - High performance data centre modules that will utilise excess power from topsides and / or wind turbine

- TRL 1-4 Early Development

Multiple new projects at scale are emerging this year with a focus on CCS enabling technologies at all stages including transportation, well and tree design, subsurface assessments for reservoir containment and assessment of risk for storage in existing abandoned reservoirs. New this year are monitoring, measurement and verification of CO2 injection into depleted gas reservoirs.

- CO2 Injection Well Design - Cement Sheath Modelling. Initial flow assurance results have indicated cryogenic injection conditions for most of the wells’ design life. This technique looks at the impact of cold temperatures on the effectiveness of the annular cement sheath over the life of the well and post abandonment.

- TRL 9 Proven Technologies

- In-line inspection for offshore pipeline repurposing - Offshore pipelines repurposed for CO2 transportation. Fracture and corrosion assessment can be done and in-line inspection using intelligent pigs can confirm assumptions and results from this assessment.

- TRL 5-7 Late Development/Pilot

- TRL 5-7 Late Development/Pilot

- Qualification testing for well elastomers - Existing elastomers are not qualified for anticipated low temperatures or for the CO2 and accompanying impurities expected in the stream captured from emitters. Lab testing and qualification activity will enable appropriate elastomer material selection for new CO2 injection wells.

- TRL 5-7 Late Development/Pilot

- Subsurface CO2 Storage Assessment - Subsurface modelling, potentially incorporating new data acquisition and processing to allow modelling of CO2 injectivity, migration and containment to better understand the risks involved. Tools to critically assess and assure containment within the reservoir, including the impact of P&A’d wells in existing reservoirs.

- TRL 5-7 Late Development/Pilot

- Carbon capture utilisation and storage - CCUS applications for reducing GHG emissions and improving reservoir recovery through EOR. Potential to for hub developments.

- TRL 5-7 Late Development/Pilot

- TRL 5-7 Late Development/Pilot

- MMV – Measurement, Monitoring and Verification technology assessments. Preparation of MMV plans tailored to specific storage sites to enable achievement of required detectability thresholds for any given licence area. Assessment includes wide variety of available and emerging technologies.

- TRL 5-7 Late Development/Pilot

CO2 Injection Well Design - Load Case Modelling. Current well design modelling packages for burst/collapse/axial and triaxial load case design (Landmark WellCat / StressCheck) are not suitable for modelling CO2 injection in dense phase or multi-phase flow. Fit-for-purpose CO2 injection modelling software for casing and tubing is required.

CO2 transport, processing and injection simulation/ modelling – Flow assurance modelling to assess the design and operation of CO2 processing, transportation and injection into depleted reservoirs and aquifers, including all operating and design scenarios.