Well Drilling & Construction technologies have gained more widespread attention in the past 4-5 years.

In addition to technologies to deliver more difficult resources (such as geo-steering), solutions for lower-cost wells and digital well planning are showing increasing traction in the industry.

In this year’s Operators’ Plans specific designs and technologies for CO2 storage are also emerging.

Well Drilling & Construction technologies

Operators’ technology focus spreads across all aspects of well planning and delivery.

Advances in general well planning and drilling technologies are complemented by more specific technologies for special wells (e.g. extended-reach and multi-laterals) or drilled in thin reservoirs (e.g. using geo-steering)

10 Operators carry at least 5 Wells technologies in their current Plans, and 10 more Operators report at least 1 technology

This level of interest is commensurate with the number of Operators currently engaged in exploration and/or development drilling

Operators’ technology focus spreads across all aspects of well planning and delivery.

Advances in general well planning and drilling technologies are complemented by more specific technologies for special wells (e.g. extended-reach and multi-laterals) or drilled in thin reservoirs (e.g. using geo-steering)

10 Operators carry at least 5 Wells technologies in their current Plans, and 10 more Operators report at least 1 technology

This level of interest is commensurate with the number of Operators currently engaged in exploration and/or development drilling

Growth in digital well planning by using and adopting AI is reported by a larger range of operators this year. Specific design & planning technologies for CO2 storage wells are on the increase as well. Some aspects of CO2 well design are more mature this year and DHSV design is now achieving TRL 8. Emerging technologies include well metallurgy advances and drilling collision software.

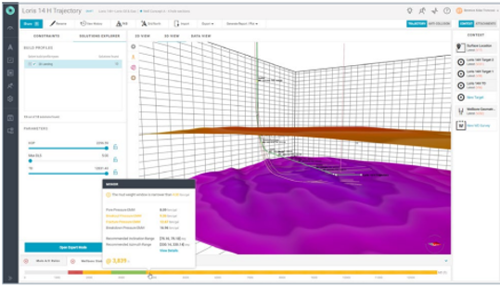

- Digital Well Planning - DrillPlan is a digital well construction planning solution that will allow you to maximize the results from your teams by giving them access to all the data and science they need in a single, common system.

- TRL 9 Proven Technologies

|

Technology Example: SLB DrillPlan Software DrillPlan* coherent well construction planning solution gives your well planning teams access to all the data and science in a single, common system. It provides the platform for a radical new way of working that gives you quicker and better-quality drilling programs by automating repetitive tasks and validation workflows to ensure your entire plan is coherent |

Link:TI 22 - 17. Technology Example - SLB DrillPlan Software.docx |

- Well Activity Reporting Portal (WARP) - Digital Well Activity Reporting Portal - to improve drilling efficiencies and working practices

- TRL 9 Proven Technologies

- Well planning using artificial intelligence - Work with external provider to develop AI well planning too. Fast turnaround alternative well path trajectory screening.

- TRL 8 Early Commercialisation

- DHSV Design for CO2 injection - Initial flow assurance results have indicated cryogenic injection conditions for the majority of the wells design life. Among the challenges associated with this is the impact of the cold temperatures on the ability of the DHSV (Down Hole Safety Valve) to successfully close and seal the well when required.

- TRL 8 Early Commercialisation

- Well Design for Carbon storage -Explore the latest CO2 well-design requirements and technology. Reinjection of CO2 in north sea depleted reservoirs presents challenges on well design such as material, low temps, flow assurance and re-entry into severely depleted reservoirs

- TRL 5-7 Late Development/Pilot

- TRL 5-7 Late Development/Pilot

- Reduce/eliminate risk of drilling collision issues caused by high well density and positional uncertainties

- TRL 5-7 Late Development/Pilot

Big bore wells and slim-hole well designs are both being utilised for specific types of ERD. Emerging technologies include digital solutions for drilling controls, technologies for high accuracy surveying while drilling, and drill bit modification and optimisation techniques.

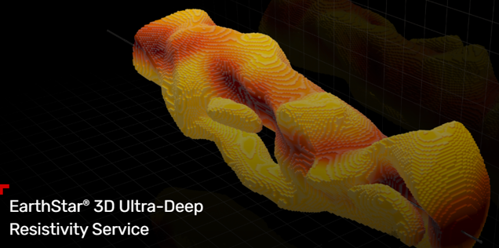

- EarthStar Ultra-Deep Resistivity Service - Advanced geosteering resistivity tool to place wells more accurately in the reservoir.

- TRL 9 Proven Technologies

|

Technology Example: The EarthStar ultra-deep resistivity service is an innovative logging-while-drilling (LWD) technology that illuminates the reservoir by revealing reservoir formations and fluid boundaries up to 225 feet (68 meters) around the wellbore. It enables operators to position production boreholes accurately while mapping large volumes of the reservoir. . |

Link:TI 22 - 34. Technology Example - Halliburton EarthStar.pdf Link:TI 22 - 34. Technology Example - Halliburton EarthStar.pdf |

- Extended Reach Drilling (ERD) with slim hole design - slim hole design be stimulated by hydraulic fracturing.

- TRL 9 Proven Technologies

- High Departure HPHT Wells - High Departure to reach near field HPHT prospects

- TRL 9 Proven Technologies

- Schlumberger DD Tools - High accuracy surveying to reduce error ellipses in ERD wells. Dual inclination and other survey tool combinations to reduce vertical and lateral error ellipses

- TRL 8 Early Commercialisation

|

Technology Example: High accuracy surveying to reduce error ellipses in ERD wells. Dual inclination and other survey tool combinations. |

Link: TI 22 - 33. Technology Example - SLB OptiDrill Software.pdf Link: TI 22 - 33. Technology Example - SLB OptiDrill Software.pdf |

- Drill Bit Modification and Optimisation -Research and development with service companies to continue to drive reliability, durability and reduce trips

- TRL 5-7 Late Development/Pilot

Drilling Equipment sub-category continues to show high quality solutions for improving well access for interventions, managed pressure drilling technologies and low-cost platform workover rigs/modular drilling rig systems.

- Use of MPD - Use of active MPD with statically balanced and statically under balanced drilling fluids in HPHT environment

- TRL 9 Proven Technologies

- A number of low-cost platform retrofittable workover rigs are being adopted such as Dwellop’s Lynx Mast and Wellvene’s WellHop lightweight wireline system, and Streicher modular drilling rig systems

- TRL 9 Proven Technologies

|

Technology Example: The new 90’ LynxTM Wire Line Mast is setting a new industry standard. Introducing superior efficiency, increased working environment and without the need for external cranes once installed. Also features BOP access in compliance with Norsok S-002. |

Link: TI 22 - 27. Technology Example - Lynx Mast.pdf Link: TI 22 - 27. Technology Example - Lynx Mast.pdf |

- Accurate Measurement of casing setting depth in pressure transition zone above reservoir - Small drilling margin in pressure transition zone

- TRL 8 Early Commercialisation

- Baker CICM (Casing Integrity & Cement Mapping) tool - Used to measure casing wear. Technology has not been run in the UK North Sea. Collect casing and cement integrity measurements any time you run drill pipe in the well, Reduce cost and rig time required to obtain well integrity data, Eliminate the need for a dedicated logging run

- TRL 8 Early Commercialisation

|

Technology Example: Collect casing and cement integrity measurements any time you run drill pipe in the well, Reduce cost and rig time required to obtain well integrity data, Eliminate the need for a dedicated logging run. |

Link: TI 23 – 14. Technology Example – Baker Hughes XSight.docx Link: TI 23 – 14. Technology Example – Baker Hughes XSight.docx |

- Streicher Continuous Circulating System – Streicher Continuous Circulating System (when tripping drill pipe) Enables lower mud weights to be used when drilling depleted reservoirs. Gives the ability to maintain ECD when making or breaking connections

- TRL 6-7 Late Development/Pilot

LWD, MWD & Geosteering – operators are using deployable technologies such as digital software using Machine Learning and AI for looking ahead of the bit during Geosteering and logging while drilling. Emerging technologies include HFTO (High Frequency Tortional Oscillation) dampening.

- Schlumberger Geosphere - Geosteering in thin reservoir intervals using LWD resistivity imaging technology to look ahead of the bit through inversion.

- TRL 9 Proven Technologies

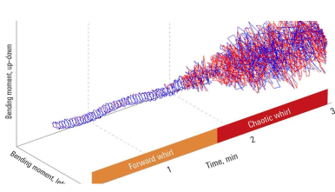

- CoPilot3 - In combination with HFTO dampener tool, CoPilot3 used to control torque applied at bit thus ensuring HFTO dampener tool operates within limits, but also optimizes downhole WOB, which appeared to improve ROP on first application compared to a direct offset well.

- TRL 9 Proven Technologies

|

Technology Example: The CoPilot™ ultra-high-definition (UHD) service measures downhole drilling dynamics in real-time and records ultra-high-definition data to memory during dysfunctional drilling events |

Link: TI 22 -16. Technology Example - CoPilot UHD.PDF Link: TI 22 -16. Technology Example - CoPilot UHD.PDF |

A range of deployable technologies for Drilling, Casing & Cementing are reported including; high temperature drilling muds, downhole drill parameter monitoring, expandable casing patches to aid slot recovery. Emerging technologies include small margin drilling in pressure transition zones, digital benchmarking tools & real time well engineering.

- Perf & Wash cement placement - Perf & Wash cement placement provides a lateral isolation across two separate isolation intervals

- TRL 9 Proven Technologies

- Therma bore high temperature mud - Therma bore high temperature mud in the Bacchus reservoir.

- TRL 9 Proven Technologies

- Purebore Rheology mud - For a thinner and tougher filter cake, Pure-Bore system has a highly shear thinning rheology, no bit balling, improved ROP, significant shale encapsulation, and improved solids control efficiency

- TRL 9 Proven Technologies

|

Technology Example: Pure-Bore® system has several advantages such as a highly shear thinning rheology, no bit balling, improved ROP, significant shale encapsulation, improved solids control efficiency through finer shaker screens hence reduced dilution volumes. |

Link: TI 22 - 36. Technology Example - Pure-Bore Drilling Mud.docx Link: TI 22 - 36. Technology Example - Pure-Bore Drilling Mud.docx |

- Expandable Casing Patch - Identified risk of leak in existing 13 3/8" casing. As part of slot recovery programme, expandable casing patch was deployed to remediate. Patch was sized to allow subsequent drilling and casing cementing through the patch

- TRL 9 Proven Technologies

- tde proNova digital benchmarking tool – Knowing the rig, crew and fleet performance with comprehensive visualisations, analytics, and benchmarking to detect potential savings.

- TRL 9 Proven Technologies

- Real time well engineering, Ensuring optimal drilling is accomplished maximises the productivity of drilling activities.

- TRL 9 Proven Technologies

- Small Margin Drilling in Pressure Transition Zone - Accurate Measurement of casing setting depth in pressure transition zone above reservoir

- TRL 8 Early Commercialisation

This sub-category includes deployable technologies such as hydraulic fracturing to improve poor reservoir quality, and modular subsea injection systems using multiple fluid injections for either scale removal or hydraulic fracturing.

- Application of Hydraulic fracturing in Cygnus - 10th infill well is planning to drill a vertical, hydraulically fractured well to develop poor reservoir quality areas. This will be the first application of hydraulic fracturing in Cygnus.

- TRL 9 Proven Technologies

- Scale Squeeze with Degraded Intervention Barriers – MARS OneSubsea - Scale squeeze deployed from DSV rather than LWIV

- TRL 9 Proven Technologies

|

Technology Example: OneSubsea MARS - Providing low-cost, low-risk intervention - cost-effective wellhead processing. MARS system technology can be used for both vertical and horizontal production trees in surface and subsea applications. |

Link: TI 22 - 29. Technology Example - OneSubsea MARS.pdf Link: TI 22 - 29. Technology Example - OneSubsea MARS.pdf |

Operators’ technology plans for 2023 show adoption of multi-function wireline tool-strings and intelligent completions. Increased activity is reported for carbon storage related technologies including DHSV, multiset well plugs and well designs for CO2 injection wells.

- Combined Wireline Toolstrings - "Single run toolstring to punch tubing and set straddle for use in retro-fit gas lift applications. Saving a toolstring run on LWIV operations. Bridge Plug with integrated Junk Catcher, again saving an additional wireline run."

- TRL 9 Proven Technologies

- HPHT Interwell Insert Valve (IVC) Carrier with SCSSSV - The IVC astraddle with SCSSSV will replace the currently deployed straddle to stop the hydraulic fluid passing into the tubing side via the top packer of the straddle.

- TRL 9 Proven Technologies

- CO2 Injection Well Design - DHSV Design - Initial flow assurance results have indicated cryogenic injection conditions for the majority of the wells design life. Among the challenges associated with this is the impact of the cold temperatures on the ability of the DHSV (DownHole Safety Valve) to successfully close and seal the well when required.

- TRL 8 Early Commercialisation

- Multiset Well Plug - Multiset well plug with an electric setting tool will allow the plug to be set and unset repeatedly in a single run.

- TRL 8 Early Commercialisation

|

Technology Example: Multiset well plug - Interwell Retrievable HPHT Bridge Plug with an Electric Setting tool will allow the plug to be set and unset. Link: TI 23 – 81 Technology Example – HPHT Well Plug and Electric Setting tool.docx |

Retrievable HPHT Bridge Plug Electric Setting tool |